Manufacturing ERP

Businessi Manufacturing ERP

Manage Sales, Production, Inventory and Everything under One Platform

Simplest, Modern ERP for Small Manufacturing

Business i Manufacturing ERP software helps you to optimize your small business and allows you to meet your customer requirements more effectively. This provides you with more customers. We are here to show you some reasons why your business needs Manufacturing ERP software.

As we are well-experienced with our technical professionals and strategists, we provide exemplary solutions to our clients to reach their business goals.

With Business i, you can

Planning and executing out production

Enable operators to record production data on smart devices for real-time visibility on the businessi platform.

Order Monitoring

Get complete access to orders. occupied and following orders across the shop floor

Maintenance Management

To extend asset life and save downtime, schedule maintenance, and monitor asset utilization.

Quality Control

Make Real-Time Production Quality Records available and keep a careful eye on materials and procedures.

Increase the growth of your business

Increase Productivity & Realtime Tracking

Customer Satisfaction

Meet all requirements with one system

Streamline and Manage all the Moving Parts of your Production

Why Small Manufactures choose Businessi?

As our production ERP Software is designed according to your specific requirement and can provide benefit to your business in many ways. We are here to show you some reasons why your business needs Manufacturing ERP software.

Accurate Planning

As BOM management software helps you to get the best result to get the accurate plan to provide the on-time delivery.

Immediate update

BOM ensures you notify automatically whether minimum stock or no stock has required in the system.

Calculate the cost

Implementing the BOM (bill of material) for your business helps you to calculate optimize the usage of material & helps in reducing waste.

Control inventory and stock

MRP is the system that assists you to controlled inventory, stock movements, tracking serial numbers, shipments, and still more.

Reliable production schedule

Material Requirement Planning (MRP) assists you to manage production and plan accurately and helps to occur a reliable production schedule.

product demand

You can determine the total demand for your products, and the no of raw materials required to meet the demand by inventory valuation, calculation, product costing, etc.

Fast-Track your Manufacturing business

Involved in some major ways like inventory management, MRP (Material Requirement Planning)in real-time.

Helps you to track the various process which is associated with quality management and monitor the product at every step.

Product planning & scheduling

Product planning and scheduling management is the best method to utilize all the resources available in the industry. Production planning& scheduling managed by businessi ERP software not only helps you in planning the production but also makes sure that machines and equipment are maintained well.

- Schedule regular maintenance

- Reduce the usage of resources.

- Smooth and reliable workflow of business.

- Help to delivers the product on time

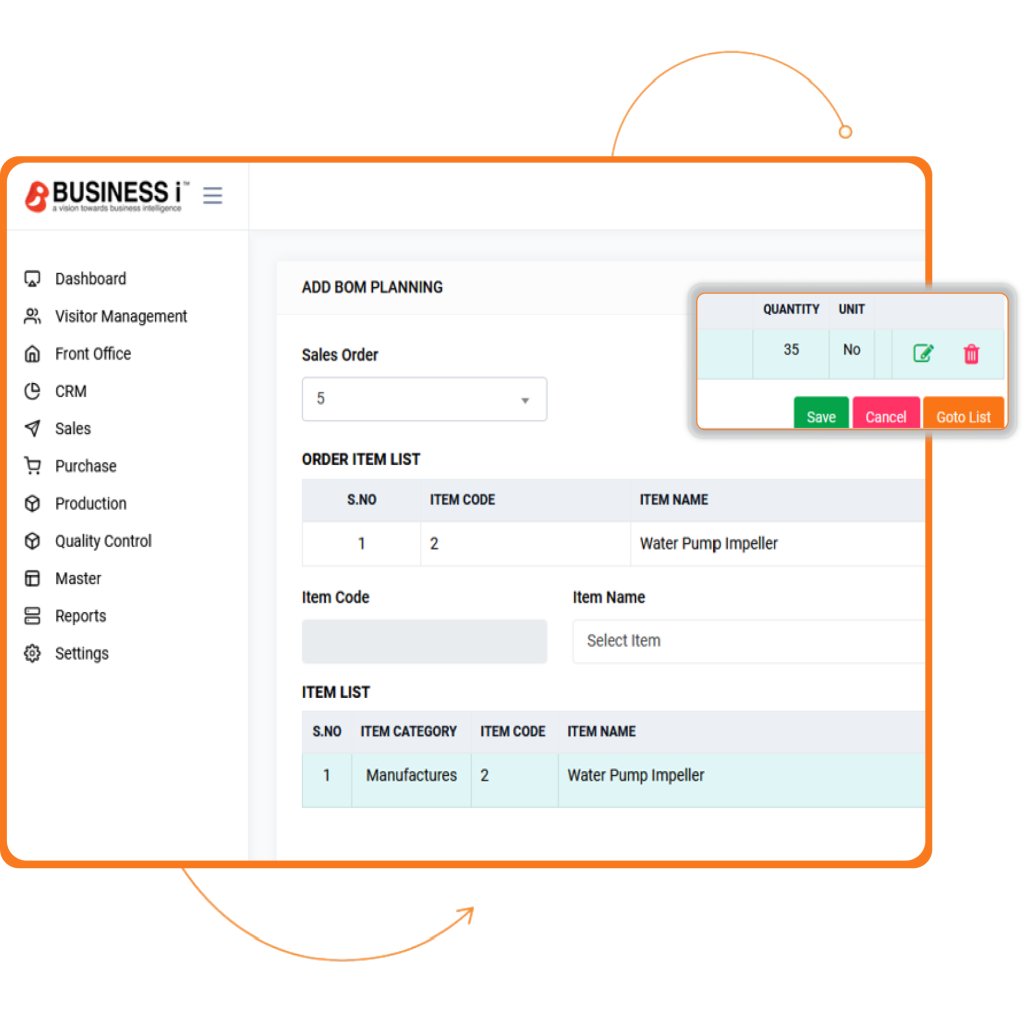

Bill of the Material - BOM

Helps to instruct how to be procuring of materials.

BOM involves all the necessary components of manufacturing products.

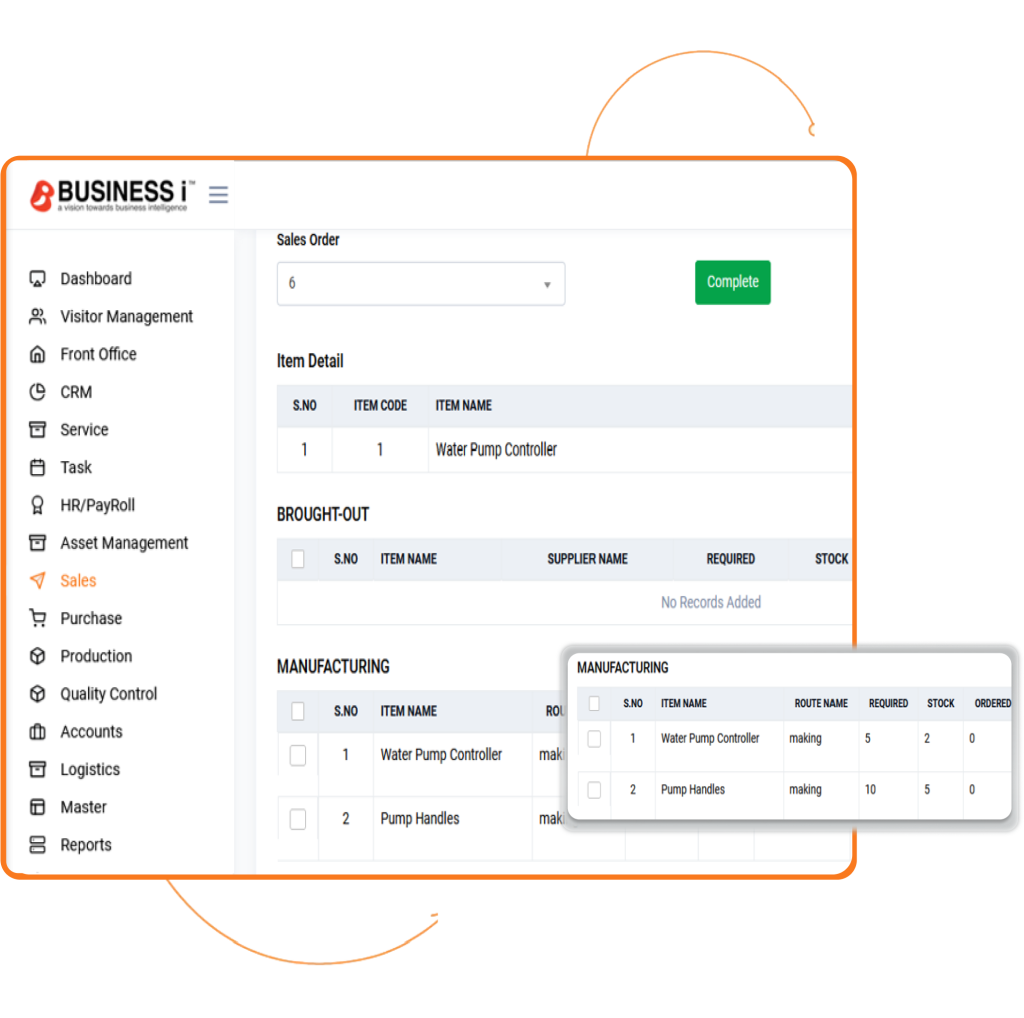

Material Requirement Planning-(MRP)

Business i ERP system designed the MRP management to plan manufacturing production of your company.

MRP helps to identify the necessary materials and estimated quantities

Regulates when materials will be required to meet the production schedule

Handle the delivery within the time to achieve the goal of meeting demands

Benefits of using Business i ERP for Manufacturing Businesses

Make each pipeline’s individual stages unique.

Get to know their past purchase orders or which stage of the buying process they are currently in.

Visually monitor the progress of your transactions.

Manufacturing ERP FAQs

Businessi offers a variety of tools to manage diverse industrial processes on a single platform. With only single software tool, you can efficiently manage your whole workload.

On businessi, you can effortlessly generate professional invoices that adhere to GST. Also, you may quickly email them to anyone. You can prepare many small business-related papers, including sales orders, purchase orders, notes for products received, challans, and more.

A bill of materials (BOM) is an ordered list of the components—raw materials, subassemblies, and intermediates—and the quantities of each required to make the finished assembly or saleable product.

Businessi Manufacturing Software is used by manufacturers such as those who make machines, bearings, food, pumps, etc. to manage their processes. One piece of software may control the entire production process from beginning to end.

- Streamline operations in business

- highly customizable and secure

- Increased ROI

- minimize mistakes

- quicker deliveries

- improved efficiency

- Unified view of data

- Cash Management