ERP Built for Food & Beverage Manufacturers

Manage recipes, batches, quality checks, inventory, and compliance from raw ingredients to packaged products.

- Batch & Expiry Tracking

- Recipe & Yield Management

- Food Safety & Quality Compliance

Core Features for Manufacturing Success

Production Planning

Plan daily and seasonal production efficiently by aligning raw materials, machines, and workforce with demand.

Material Requirement Planning

Automatically calculate raw material requirements based on production plans to reduce wastage and stock shortages.

Inventory Tracking

Track inventory by batch, expiry date, and storage conditions to minimize spoilage and maintain freshness.

Batch Management

Manage recipes, batch sizes & ingredient proportions while maintaining consistency across every production run.

Quality Control

Ensure food safety standards with built-in quality checks, batch traceability, and compliance reporting at every stage.

Costing Management

Control product costing by tracking ingredient, packaging, and processing costs for better pricing and profitability.

Take Control of Quality, Compliance, and Production

Reduce wastage, ensure food safety, and deliver consistent quality every time.

Industry-Specific ERP Solutions

Bakery Industry ERP

Dairy Processing ERP

Meat & Poultry ERP

Beverage Production ERP

Frozen Foods ERP

Confectionery ERP

Snack & Ready-to-Eat ERP

Success Stories & Testimonials

Stay in Control of Your Food & Beverage Operations

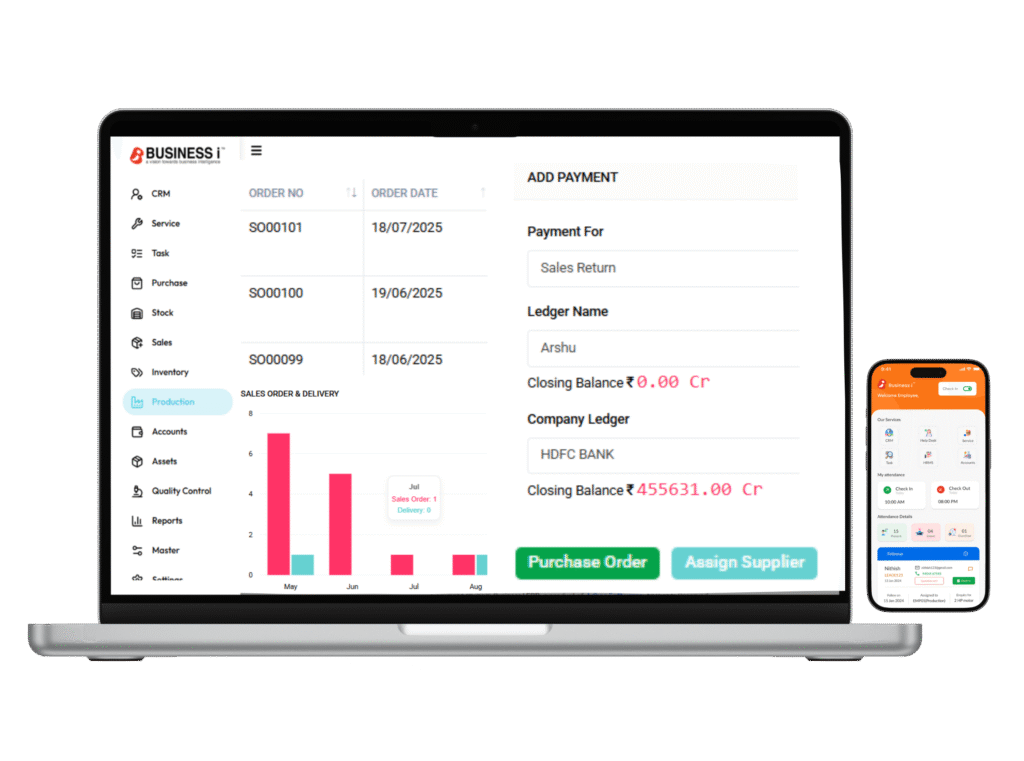

Business i ERP helps you stay in control by giving clear visibility into production, quality, and daily operations without adding complexity.

Batch Control

Track batch-wise production and recipe usage to ensure consistency in taste, portioning, and output across shifts or locations.

Quality & Safety Tracking

Record quality and hygiene checks at different stages to maintain standards, reduce rejections, and support food safety requirements.

Production & Wastage Visibility

Monitor daily production, material usage, and wastage to understand where losses occur and take corrective action early.

Frequently Asked Questions

Food & Beverage businesses deal with batch production, expiry-sensitive inventory, and tight margins. An ERP system helps bring inventory, production, sales, and costs into one system, reducing wastage and improving control over daily operations.

Yes. The ERP supports batch-wise tracking with expiry and shelf-life monitoring, helping businesses maintain quality, trace products easily, and reduce losses due to expired stock.

Yes. With real-time inventory updates and usage tracking, the system helps identify overconsumption, wastage, and stock gaps, allowing better planning and cost control.

Yes. The ERP can manage production at manufacturing units while also tracking sales and stock across multiple outlets or locations from a single dashboard.

The system is designed to be simple and role-based. Staff only see the features they need for daily work, and focused training helps teams start using the system without long learning curves.