All-in-One Manufacturing Workflow Management

Business i ERP for the manufacturing industry helps you run your small business more efficiently. It makes it easier to meet customer needs and bring in more business. We’ll show you why choosing the right ERP can make a big difference for your manufacturing process. With our skilled technical experts and smart strategies, we provide solutions that help you reach your goals faster and more effectively.

Key Features of Business i ERP for Manufacturers

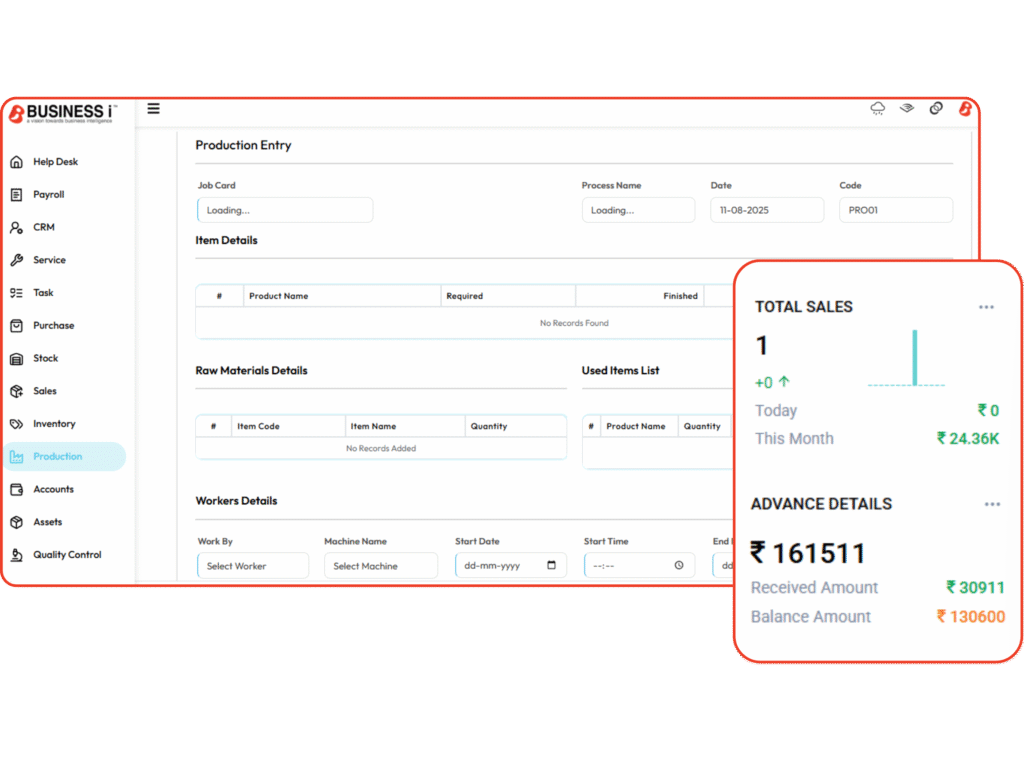

Production Management

Real-time production tracking and execution using smart devices for better operational control

Order Monitoring

Monitor and track incoming and in-process orders across the shop floor for improved efficiency

Manufacturing Workflow Process

Business i ERP is designed to streamline every stage of production from initial planning to final delivery. By integrating advanced tools like BOM and MRP (Material Requirements Planning), it ensures resources are used efficiently, orders are tracked in real-time, and quality standards are maintained at every step.

Optimize Resources: Maximize efficiency by intelligently allocating manpower, machinery, and materials using Business i ERP’s integrated planning system. With built-in support for Bill of Materials (BOM) and Material Requirements Planning (MRP), you can preemptively identify resource demands and coordinate production schedules accordingly. production flows seamlessly

Accurate Scheduling: Create realistic, dependable production schedules that reflect actual capacity, maintenance windows, and customer deadlines. Business i ERP synchronizes demand forecasting, resource availability, and job sequencing to ensure tasks are executed in the right order, at the right time.

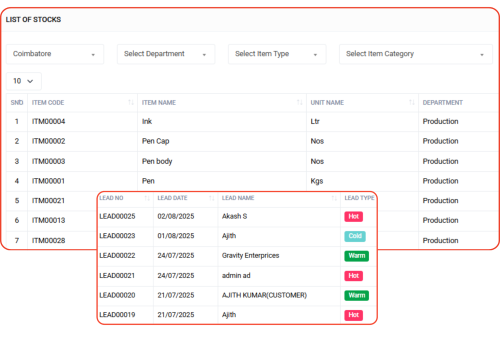

Real-Time Visibility: Get a live view of your entire production floor. Business i ERP lets you track every order from start to finish with real-time updates. Instantly know which orders are in progress, which are pending, and what’s coming next. This helps your team avoid confusion, reduce idle time, & stay fully informed so nothing falls through the cracks.

Seamless Coordination: Keep your teams connected at every step. Business i ERP links production, inventory, and dispatch teams in one platform. As soon as an order moves to the next stage, everyone gets notified. This means no missed updates, no manual follow-ups, and no delays just smooth, on-time order fulfillment.

Continuous Monitoring: Stay on top of product quality every step of the way. With Business i ERP, you can monitor and record inspection results in real-time during each stage of production. This helps you catch issues early, reduce rework, and ensure that every product meets your quality standards before it reaches the customer. By tracking quality as you go, you save time, lower costs, and protect your brand reputation.

Data-Driven Improvement: Turn quality checks into actionable insights. Business i ERP collects and analyzes inspection data to help you spot patterns, recurring defects, or weak spots in your process. Use these insights to fine-tune your operations, improve materials or methods, and continuously raise your production quality.

Take Control of Your Production, Start Today

Whether you're producing 100 or 10,000 units a month, Business i gives you the tools to plan better, produce faster, and grow without limits.

Bring Innovation to Your Company

Start planning your vacation with our trip guides, It’s time to explore the world. Capture everything!

Zoho

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- List Item #1

- List Item #2

- List Item #3

SAP

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- List Item #1

- List Item #2

- List Item #3

Business i

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- List Item #1

- List Item #2

- List Item #3

Why Your Business Needs Business i ERP For Manufacturing?

Accurate Planning

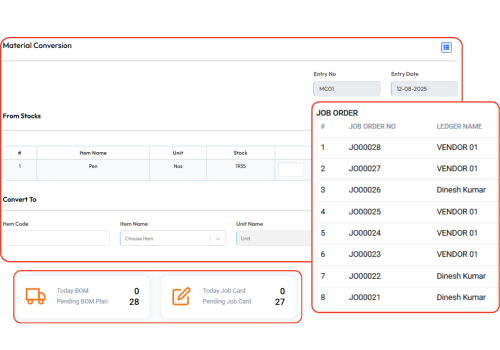

The Bill of Materials (BOM) helps you plan production accurately by listing every component, raw material, and part needed to make a product. With Business i ERP, you can easily create detailed BOMs to guide purchasing, avoid material shortages, and prevent excess stock.

Instant Stock Alerts

Get instant alerts when your inventory hits the minimum level or needs restocking. With Business i ERP’s smart alert system, you’ll always know when stock is running low, helping you avoid production stops, delivery delays, or missed sales.

Faster Production Cycles

Business i ERP’s Material Requirements Planning (MRP) system ensures that the right materials are available at the right time for every stage of production. It automatically calculates material needs based on current orders, stock levels, and lead times, helping you avoid delays caused by missing components.

Data-Driven Decisions

Gain complete visibility into your business performance by analyzing real-time data on costs, sales, and inventory usage. Business i ERP provides detailed reports and dashboards that help you identify spending patterns, high-performing products, and underutilized resources.

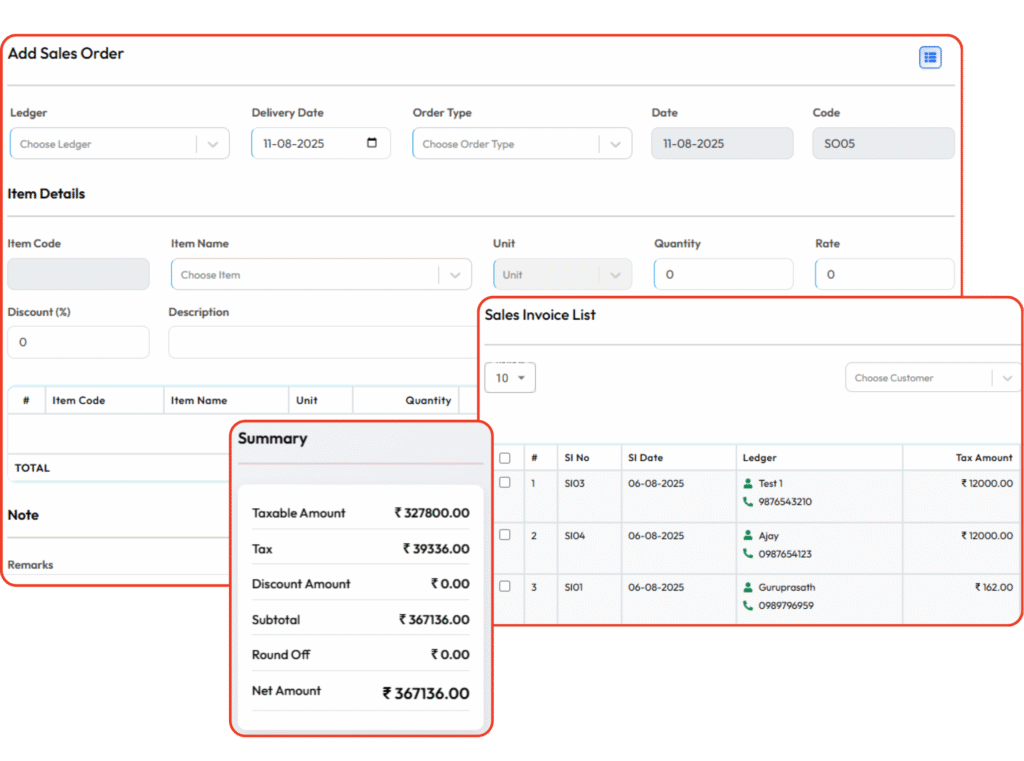

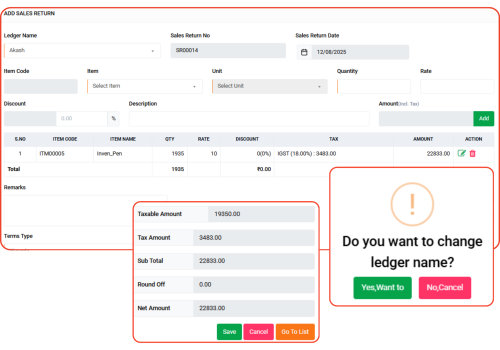

Easy Sales Integration for Smarter Order Management

Business i ERP doesn’t stop at production it connects seamlessly with your sales process. When a new order is placed, it’s automatically linked with production planning, inventory, and delivery timelines.

- View customer orders alongside production status

- Auto-generate job cards and delivery schedules

- Track each order from sales confirmation to dispatch

- Eliminate manual data entry between departments

Why Businesses trust Business i for Manufacturing?

Frequently Asked Questions

Business i offers a variety of tools to manage diverse industrial processes on a single platform. With only single software tool, you can efficiently manage your whole workload.

On businessi, you can effortlessly generate professional invoices that adhere to GST. Also, you may quickly email them to anyone. You can prepare many small business-related papers, including sales orders, purchase orders, notes for products received, challans, and more.

A bill of materials (BOM) is an ordered list of the components—raw materials, subassemblies, and intermediates—and the quantities of each required to make the finished assembly or saleable product.

Businessi Manufacturing Software is used by manufacturers such as those who make machines, bearings, food, pumps, etc. to manage their processes. One piece of software may control the entire production process from beginning to end.

Business i Manufacturing ERP empowers manufacturers with an all-in-one platform to streamline operations, reduce costs, and improve productivity. By integrating every aspect of your manufacturing process into a single system, you gain: